Representing a coordinated and proactive approach to leveraging digital technologies and create step-change improvement in industrial operations, Industrial Transformation is currently being driven by the advent of Industry 4.0.

But how did we get to Industry 4.0?

Before 4.0, there was Industry 1.0, 2.0 and 3.0, each shaping Industrial Transformation in its time and representing an enormous leap in the availability of industry-defining technologies throughout the supply chain and logistics sectors.

INDUSTRY 1.0

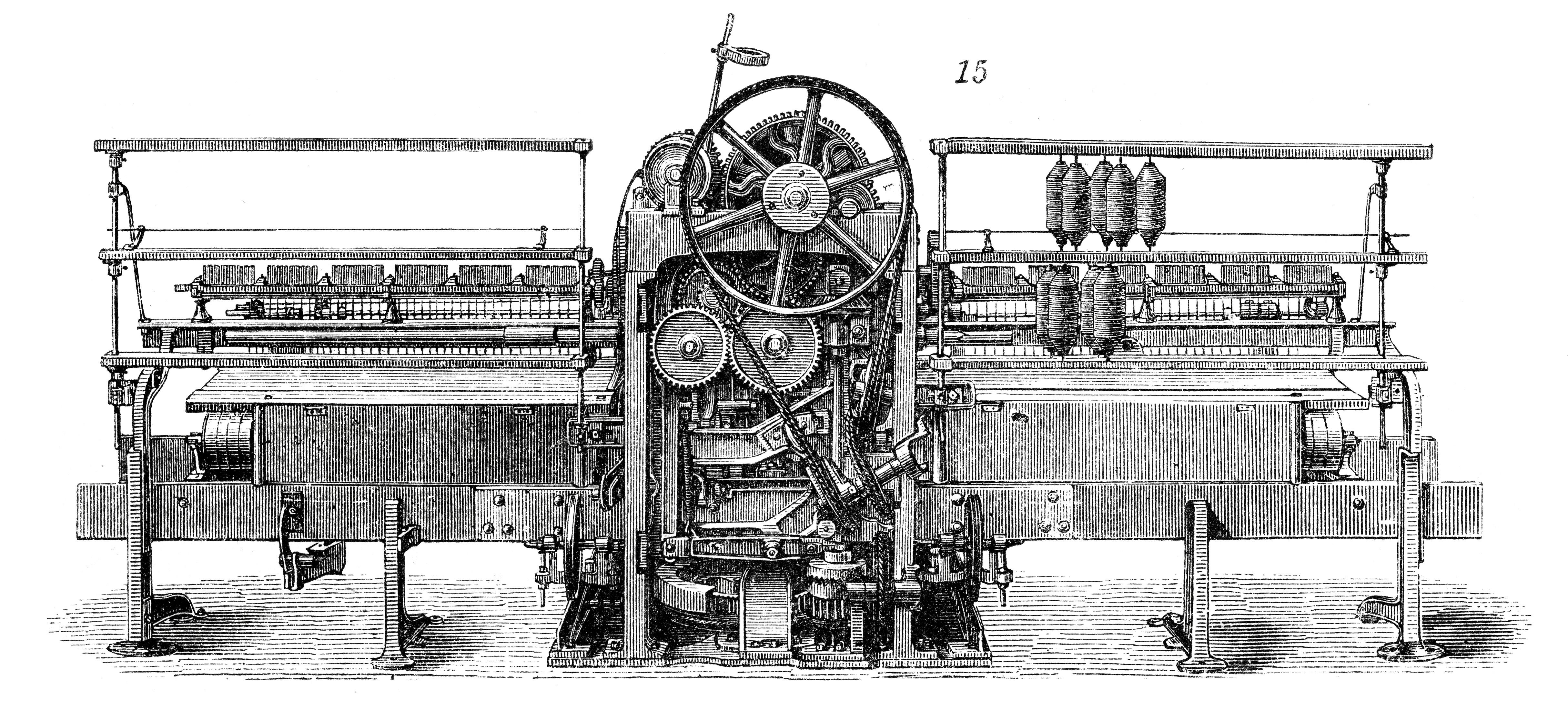

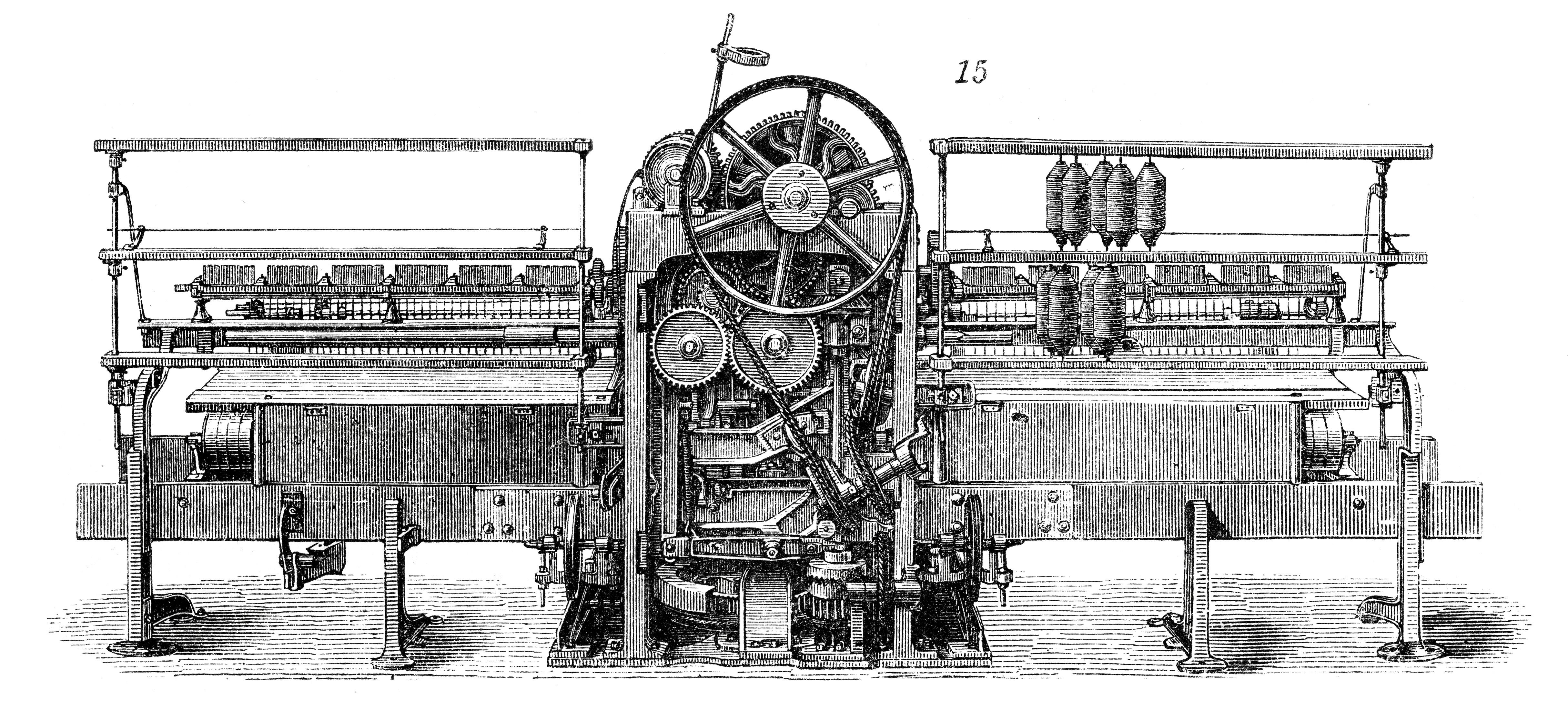

Industry 1.0, otherwise known as the Industrial Revolution, is perhaps the most present time in Industrial Transformation throughout popular culture, spanning the 1760s to around 1840. This was the transition from a handicraft economy to the use of machines and was heavily powered by the machination of production and the standardisation of steam and water power. For example, Industry 1.0 represents the advent of technologies such as the water wheel, weaving loom, and steam engine.

Industry 1.0, otherwise known as the Industrial Revolution, is perhaps the most present time in Industrial Transformation throughout popular culture, spanning the 1760s to around 1840. This was the transition from a handicraft economy to the use of machines and was heavily powered by the machination of production and the standardisation of steam and water power. For example, Industry 1.0 represents the advent of technologies such as the water wheel, weaving loom, and steam engine.

This led to more efficient and cost-effective production, meaning higher quality goods and increased growth and development in small businesses to become large organisations, with especially significant benefits to be found in the textile and transportation industries.

Industry 1.0 truly began in Australia in 1815, when the first steam engine began operating, brought to the country by Scottish engineer John Dickson. By the 1830s, steam engines were being manufactured in country, and Australia had begun to move away from the human, animal and wind powers that had defined its industry to that point.

INDUSTRY 2.0

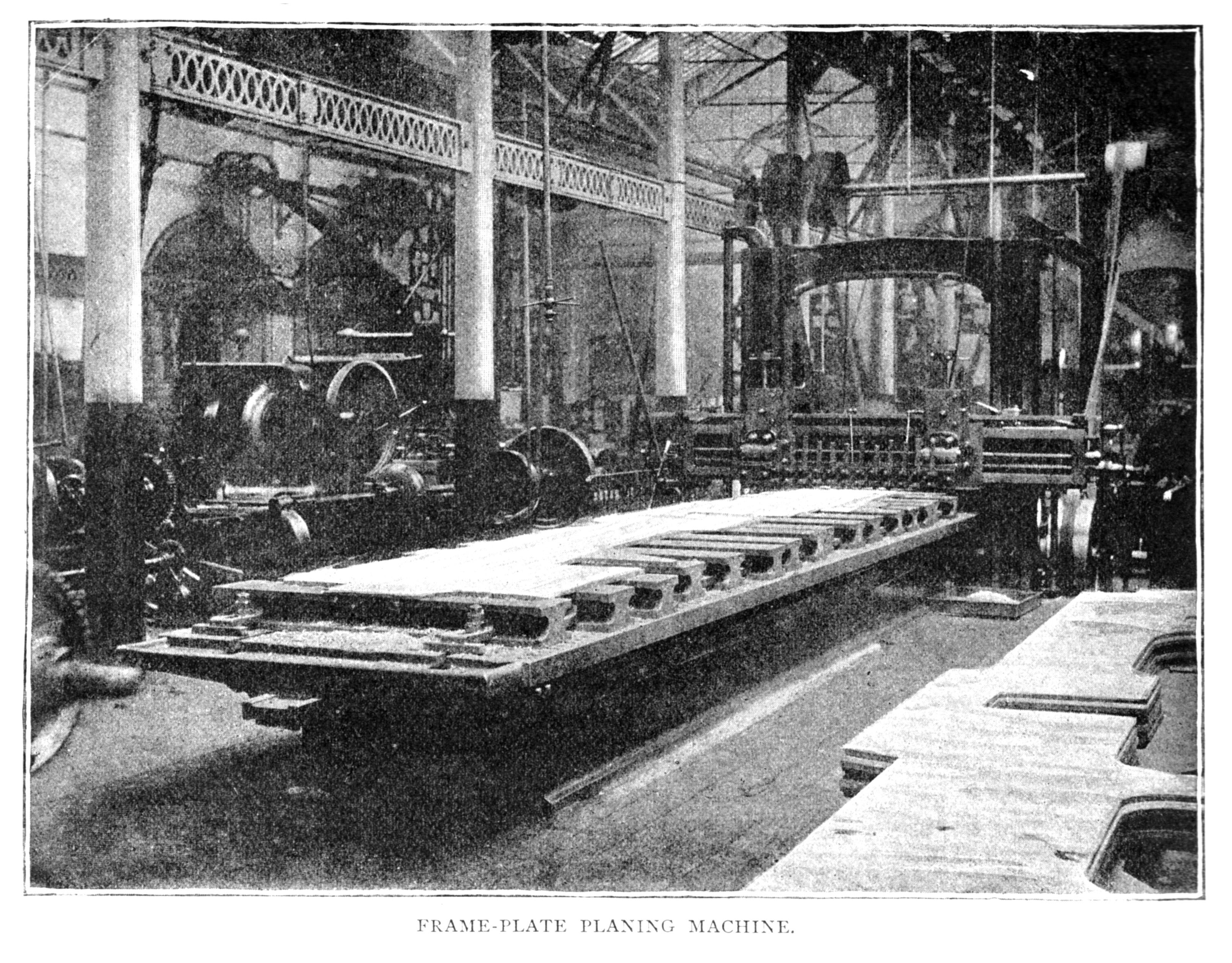

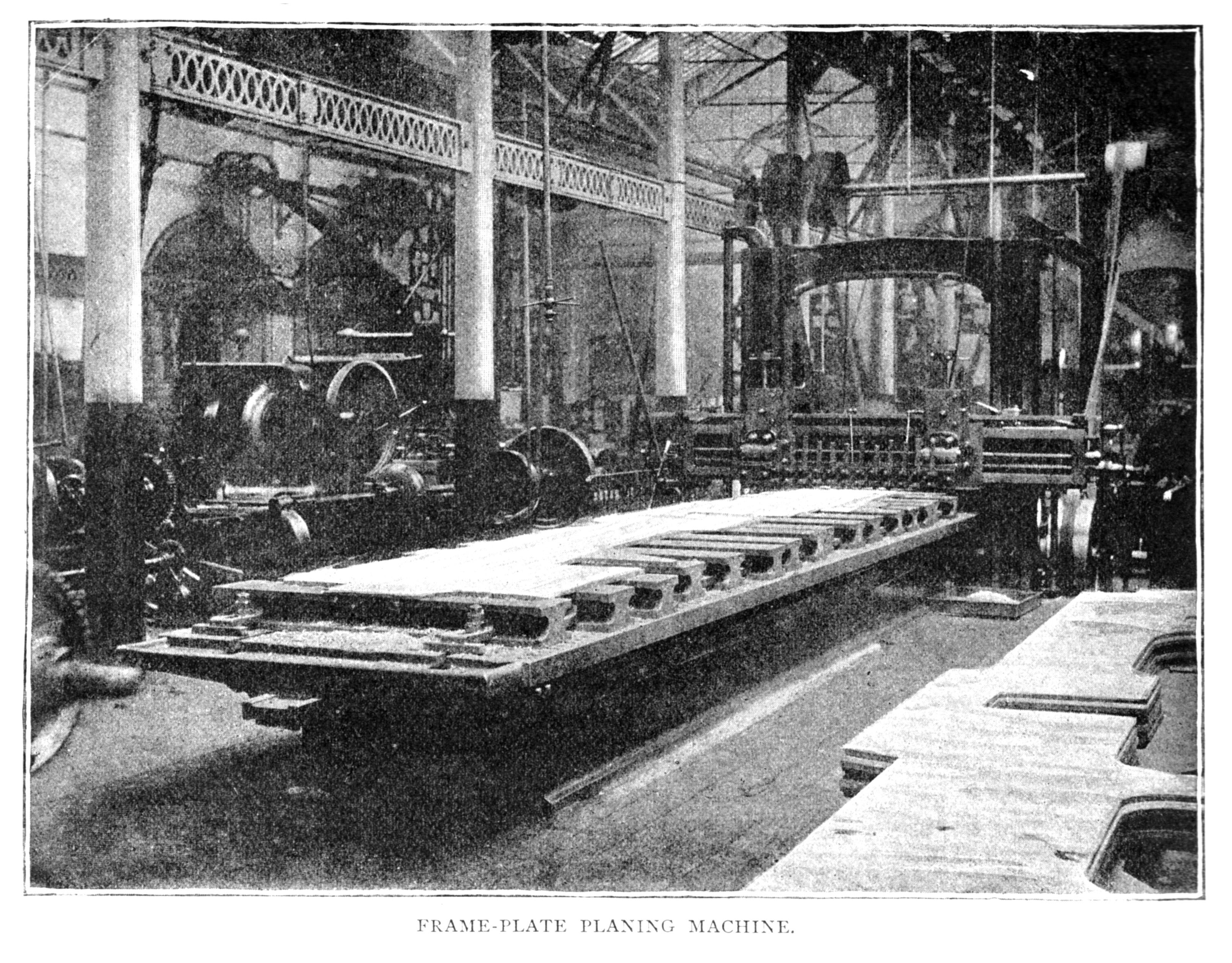

Industry 2.0, commonly known as the ‘Technological Revolution’, represents the introduction of electrical machinery, assembly lines, and, by extension, the standardisation of mass production. Beginning in Europe in the 1870s, this led to improvements in the allocation of resources, output quality and an overall better division of labour than in the Industrial Revolution, where long hours and significant manpower was required.

Industry 2.0, commonly known as the ‘Technological Revolution’, represents the introduction of electrical machinery, assembly lines, and, by extension, the standardisation of mass production. Beginning in Europe in the 1870s, this led to improvements in the allocation of resources, output quality and an overall better division of labour than in the Industrial Revolution, where long hours and significant manpower was required.

Perhaps the most important advancement made within this period was the establishment of the first ever assembly line by Ransom E. Olds. The producer of Oldsmobile cars, Ransom started a system of production producing at least 20 units a day. Throughout 1901, the year it was introduced, the company’s production increased by 500%, and served as a model for Henry Ford’s famous conveyor belt system, where specific machines would build cars step-by-step.

Industry 2.0 also represented the largest leap of Industrial Transformation Australia had ever seen, with the completion of the Overland Telegraph Line in 1872 and more common and widespread railway systems created faster travel times and a more efficient communication system, both throughout the country and with the rest of the world. Suddenly, communication times with Europe dropped from months to hours and Australia had well and truly joined the march of progress.

INDUSTRY 3.0

.jpg) Commonly referred to as the ‘Digital Revolution’ or the ‘First Computer Era’, and beginning in the 1970s, Industry 3.0 laid the groundwork for modern day machines as simple, large computers were developed, capable of partial automation and logic. Before these computers, any developed simple automated system relied heavily on human intervention and input.

Commonly referred to as the ‘Digital Revolution’ or the ‘First Computer Era’, and beginning in the 1970s, Industry 3.0 laid the groundwork for modern day machines as simple, large computers were developed, capable of partial automation and logic. Before these computers, any developed simple automated system relied heavily on human intervention and input.

Information Technology and electronics were introduced in many production processes, as the invention of the Programmable Logic Controller and the use of integrated circuitry and transistors lead to greater accuracy, increased speeds, and more competent production results. These also made it more possible to efficiently implement different management processes, as activities like inventory management, enterprise resource planning, product tracking, shipping logistics and product flow scheduling became more viable.

The inventions that enabled these processes also led to incredibly important derived technologies, including the internet, modern computers, digital cell phones and microprocessors. Industry 3.0 represents the conversion of the analogue world into a modern and digital one.

By the time of Industry 3.0, the ongoing march of globalisation and the advent of new technology allowed Australia access to the newest technologies within this industrial revolution faster than any before.

INDUSTRY 4.0

Now is the time of Industry 4.0, the revolution currently shaping the world as we know it. Characterised by the use of communication and smarter information technologies throughout various industries, 4.0 is the era of production facilities, storage systems and smart machines that can trigger actions, control other devices and exchange information autonomously without any human intervention.

Industry 4.0 is ongoing, and continually changing the way people work, pulling individuals into smarter networks, increasing efficiency, and digitalising the supply chain and logistics industries. Take, for example, the ever-increasing relevance of AI and its impacts on self-organised logistics and autonomous maintenance processes. This is already leading to the next steps of 4.0, as machines learn to predict unexpected or abrupt changes in these processes as drastic improvements are continually being introduced in how goods are serviced, refined and distributed.

Australia has taken its place as a leading contributor within Industry 4.0, with game-changing automated distribution centres appearing throughout the country and large, multinational corporations maintaining a large presence throughout the major industrial areas.

Industrial Transformation represents human development, the paths we have taken to get to where we are, and the ways in which our technologies are moving into the future. To take a peek into how this future will look come to Day 3 of CeMAT Australia and remain on the cutting-edge of the ever-advancing technologies defining the intralogistics, materials handling and supply chain management sectors.

.jpg) Welcome to the forefront of Industrial Transformation! Join us on Day 3 – Thursday, 27 July – at CeMAT Australia 2023 as we dedicate the entire Knowledge Theatre program to unlocking the potential of this groundbreaking movement. Immerse yourself in the latest technology, thought leadership, and best practices across materials handling, intralogistics, supply chain management, and logistics sectors.

Welcome to the forefront of Industrial Transformation! Join us on Day 3 – Thursday, 27 July – at CeMAT Australia 2023 as we dedicate the entire Knowledge Theatre program to unlocking the potential of this groundbreaking movement. Immerse yourself in the latest technology, thought leadership, and best practices across materials handling, intralogistics, supply chain management, and logistics sectors.

Industry 1.0, otherwise known as the Industrial Revolution, is perhaps the most present time in Industrial Transformation throughout popular culture, spanning the 1760s to around 1840. This was the transition from a handicraft economy to the use of machines and was heavily powered by the machination of production and the standardisation of steam and water power. For example, Industry 1.0 represents the advent of technologies such as the water wheel, weaving loom, and steam engine.

Industry 1.0, otherwise known as the Industrial Revolution, is perhaps the most present time in Industrial Transformation throughout popular culture, spanning the 1760s to around 1840. This was the transition from a handicraft economy to the use of machines and was heavily powered by the machination of production and the standardisation of steam and water power. For example, Industry 1.0 represents the advent of technologies such as the water wheel, weaving loom, and steam engine.  Industry 2.0, commonly known as the ‘Technological Revolution’, represents the introduction of electrical machinery, assembly lines, and, by extension, the standardisation of mass production. Beginning in Europe in the 1870s, this led to improvements in the allocation of resources, output quality and an overall better division of labour than in the Industrial Revolution, where long hours and significant manpower was required.

Industry 2.0, commonly known as the ‘Technological Revolution’, represents the introduction of electrical machinery, assembly lines, and, by extension, the standardisation of mass production. Beginning in Europe in the 1870s, this led to improvements in the allocation of resources, output quality and an overall better division of labour than in the Industrial Revolution, where long hours and significant manpower was required. .jpg) Commonly referred to as the ‘Digital Revolution’ or the ‘First Computer Era’, and beginning in the 1970s, Industry 3.0 laid the groundwork for modern day machines as simple, large computers were developed, capable of partial automation and logic. Before these computers, any developed simple automated system relied heavily on human intervention and input.

Commonly referred to as the ‘Digital Revolution’ or the ‘First Computer Era’, and beginning in the 1970s, Industry 3.0 laid the groundwork for modern day machines as simple, large computers were developed, capable of partial automation and logic. Before these computers, any developed simple automated system relied heavily on human intervention and input.