10 inventory tips for managing large product ranges

Inventory management is in essence very simple. It revolves around two questions: how much should you order, and when?

What makes inventory management so complex is that everyone views it differently. A financial director looks at the capital costs and obsolete stock, for example, whereas a logistics manager often thinks in terms of the number of pallet locations and order lines. For a sales director, however, inventory means more revenue, more profit and more satisfied customers. Adding to the complexity is the fact that the ‘traditional’ supply chain no longer exists. Rather than all goods going from manufacturer to wholesaler to retailer and then on to the consumer, many of today’s supply chains have become hybrids.

So where should you hold your stock in order to offer the best customer service?

With expanding product ranges, more sales channels and more inventory points, the reality of inventory management has become far more challenging. Based on our experience of working with over 1,000 businesses around the world who use our inventory optimisation software, we have prepared these top tips:

TIP 1: FROM STRATEGY TO EXECUTION

Translate your company strategy into appropriate business rules and associated automatic scenarios. For example, a high-end department store such as David Jones and a budget store such as Target both sell white T-shirts. However, they pursue very different inventory and procurement strategies. Based on the business strategy an assortment strategy can be created, which should be translated into a stock and purchase strategy. The strategy can be embedded in the company by means of setting business rules.

TIP 2: STATISTICS NEVER LIE

Utilise (big) data! This enables you to use statistically reliable models to arrive at an accurate forecast and (often even more importantly) to calculate the appropriate level of buffer stock on a daily basis, even in the case of extremely large product ranges.

TIP 3: ABC FOR THE RIGHT FOCUS

In a large long-tail assortment it is impossible to pay equal attention to each and every product. Sharpen your focus by frequently performing a thorough forecast-based ABC/ XYZ analysis. Which products add the most value in terms of profit, revenue and/or numbers of customers?

TIP 4: TO STOCK OR NOT TO STOCK?

Bear the three-step model in mind. Does the item fit in the product range? Do you need to keep the item in stock? If so, how many units? The second step is the most important one. Much depends on the customer’s willingness to wait and the supplier’s back-office setup.

TIP 5: CHANNEL DIFFERENTIATION

Physical stores, web shops, online platforms – retailers have to manage ever-more sales channels. With expanding product ranges comes fragmentation of demand. Optimise your profit margins by allocating the right products to the right channels.

TIP 6: PRODUCT LIFE CYCLE MANAGEMENT

Keep a close eye on the life cycle of each product. Each phase requires a different owner within the organisation and a different product management mechanism. Align your inventory and procurement strategies accordingly.

TIP 7: MANAGEMENT BY EXCEPTION

It is impossible to check every individual SKU manually every day. How many exceptions are you willing and able to manage? What do you want to automate, and which decisions could/should a planner still be able to make? Make sure you achieve the right trade-off between efficiency and effectiveness.

TIP 8: COLLABORATION

Collaboration is key, both internally and externally. Share information with your suppliers to improve performance, and don’t wait too long to share information with Marketing in order to resolve inventory-related issues and potential stock shortages as effectively as possible.

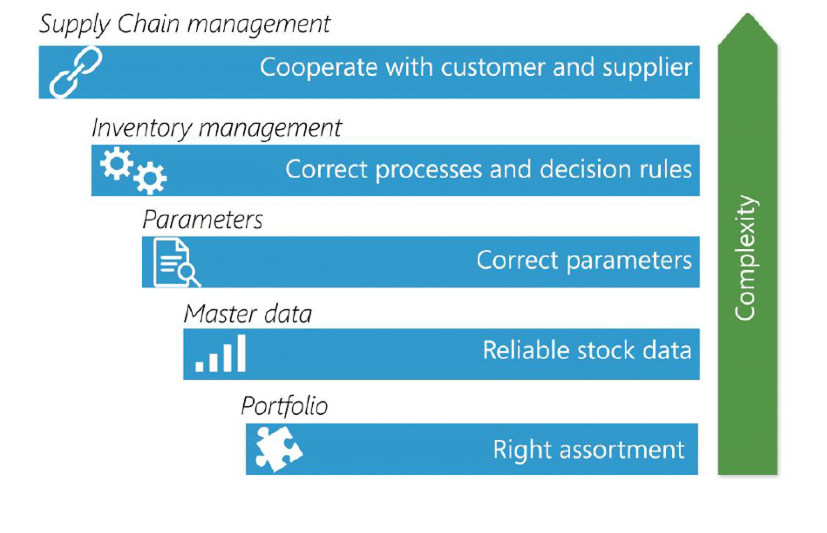

TIP 9: STEP-BY-STEP MODEL

Professionalise your supply chain one step at a time, ensuring you lay down a firm foundation. The Slimstock modular model supports a structured approach.

TIP 10: PROVIDE CONTINUOUS TRAINING

Inventory management is like a top-flight sport. Continually invest in your people to improve their competencies and keep them at your company for longer!